After nearly a week of solid rain, last weekend was bright and sunny in south east PA. With the kids half laid up with random child born diseases we weren’t going anywhere, so Sunday was forge day!1

Making this even more exciting, earlier in the week I had picked up a used 2x72” belt grinder.

Just look at the platen on that bad boy, solid as a rock! The machine is in great shape, and makes shaping things so much easier. It also runs much quieter than my other machine, so I can actually listen to things while using it. In addition to the core chassis, 1 hp motor and the platen, it came with some extra arms for attaching various alternate wheels or grinding attachments, and that really nice and heavy strand board it is sitting on keeping it from vibrating all over. Plus it has that used belt, which, despite being used still works as well or better on this machine than newer belts on the relatively feeble 1x42” I was using.

Even better the fellow who sold it to me is another local blacksmith and knife maker, Rich of Dire Wolf Forge (can be found on Etsy, although I couldn’t find it because I fail at finding anything2). Rich is a great guy, and hung out with me talking knife making and showing me how everything on the machine worked for over an hour, including helping me get it into the car3 and loaning me a cargo ratchet tie down. He has plans for getting a larger workshop space back together to host local metal workers get togethers for veterans, classes for newbies, etc. If you live in the general SE PA/Philadelphia area and would be interested in that sort of thing let me know and I will get you in touch. I know I am looking forward to the prospect of getting together with some folks to learn some new skills and just share an interest in person.

So I got a new grinder and made a new friend. A good day.

With new toys capital equipment and all day to use them, I was doubly excited to get out and finish some projects.

Project 1: That damned anvil bick/stump anvil.

I’ve been working on this for months, along side other projects, because smooshing a 1.5” bar into a right angled cone with a square bit is a lot more work than I would have thought. But it finally is done!

I mean, done in the sense that I still need to planish it a bit and grind it smooth, but it is the right shape! (Well… ok a little longer and pointier than ideal perhaps.) Still, after beating it for over a half hour, I was getting worried I wasn’t going to be able to bend it. I cannot stress enough how hard bending a 1.5” steel bar 90 degrees is, even when it is orange hot.

So, what’s this thing for? Well, in short, hammering things into round shapes. Specifically making smaller rings and curls than the anvil horn will allow, and importantly making sockets for, say, spears.

At the moment it is just a bick since it requires the square hardy hole there to hold it. When I need to I can hammer a sharper point on the square side and then I will be able to drive it into a tree stump and use it as an anvil by itself. I can also sharpen the round side and do the same to have a small, squarish anvil surface, although I don’t have a use case for that right now.

I tell you what, though, having that damned thing shaped and done is great. For months it had languished as essentially a four pound steel poo on the forge cart, but no longer. Now I can start working on spears, as well as having a handy tool for wrapped eye axes, and all sorts of things.

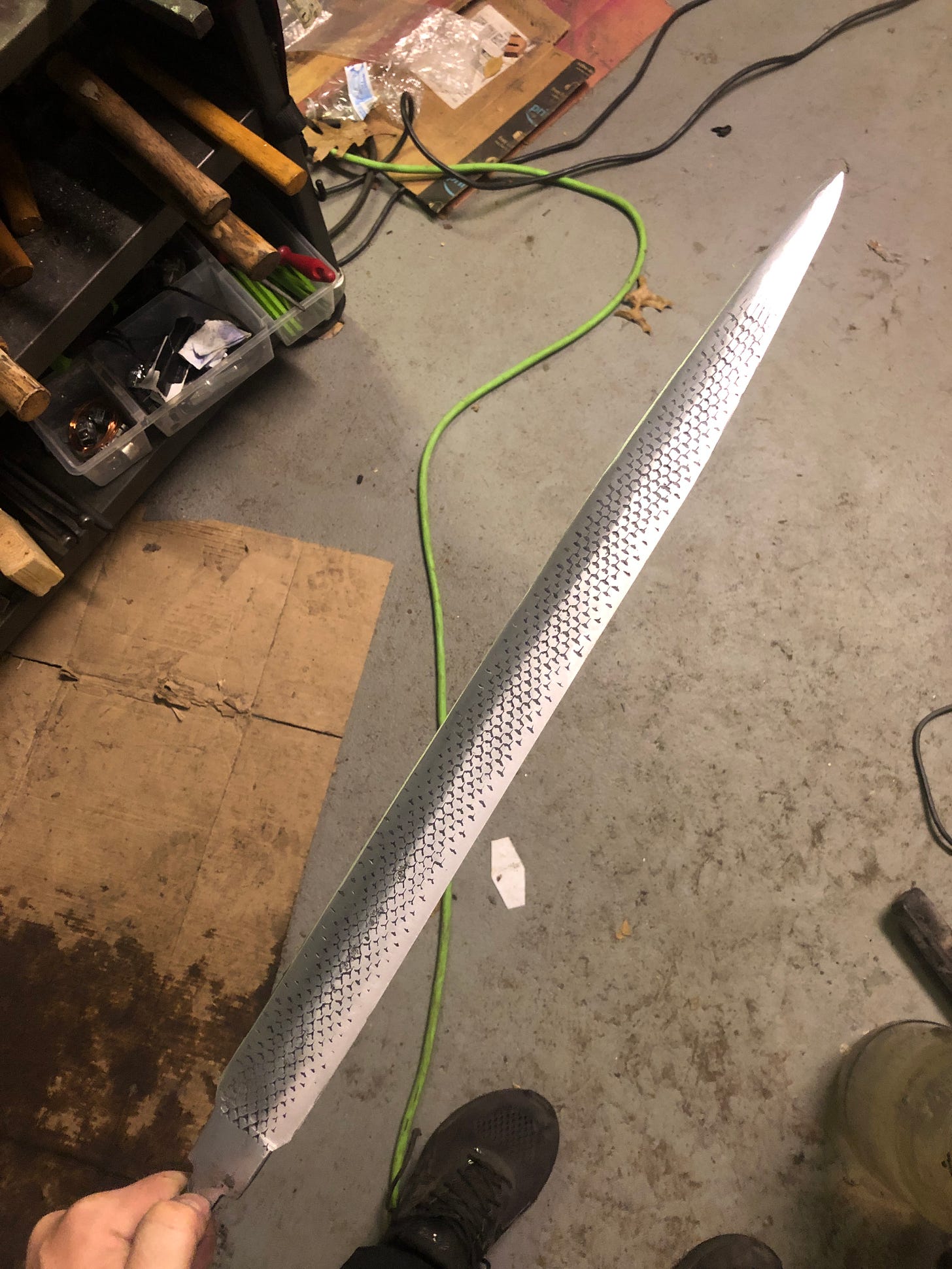

Project 2: Fishscalibur!

With a full tank of propane and some recently cut up bed frame angle irons it was finally time to heat treat the short sword. Having done that, around lunch time I took a break to eat, drink and grind, as one does.

Again, oh man that grinder… so great even though I don’t have a full set of belts yet.

Still remaining is the ring pommel. I had a clever idea, to carve a little detail work to make it less ugly that the ring wouldn’t connect. My thought was to leave it gapped till after I peened it to the tang, then close it up. The result: Ouroboros Snek!4

As you can see, I got a little excited and closed up the ring before peening. I paid for that a bit. Still, it was time for epoxy!

That hilt… the hilt has a bit of a story. I started with a 1" thick block of oak, or maple, not sure. The key thing is that the grain goes parallel to the blade, so the pattern is consistent all around. The top and bottom bits were cut out of an old bit of scrap, shaped, drilled and polished to match. Then they were attached to the wood with bolts, and the whole thing sanded and ground to be one smooth unit.

You can see them here all together. I had epoxied them at that point, but it turned out pointless because the steel was smooth enough that it didn’t really take.

There you can see the test fit on the blade. (Why yes, my side shop table is a little messy…)

Astute observers will note, however, that that isn’t the hilt in the previous photo, and they would be correct. Why? Because I had to rivet it together, and made some really nice custom brass rivets from rod to do so. As I was peening them over, however, they bent internally and then split the goddamned wood open. Yes, the wood I spent an hour or two carving out and shaping to perfectly match the angles of the steel, that wood. An angry few days later5 I cut a new bit of hardwood for a new hilt. By hand, I feel I should mention, since I didn't have access to my dad's wood shop. To avoid all the previous aggravation I cut a 1/2" piece so that I could use some existing long copper rivets I had on hand, and didn't mess about with shaping the wood till after it was riveted and shown it wouldn't split. I should have done that in the first place; be told.

The new hilt worked out, and now that everything was epoxied it was time to shape the handle and peen the pommel. After that, some stain on the wood and the sword is done!

Not perfect by a long shot. I wouldn’t be comfortable selling it, certainly, but I have no intention of selling it, and I love it. I mean, I hate it because I can see all the little mistakes I made (including the ugly peen I perpetrated because I couldn’t open up Ouroboros Snek easily and had to peen at a bad angle) but it is fabulous. The blade takes a very nice edge, and should slice through bottles and excess produce beautifully.

Next step to wrap up the project is to make a sheath. I think I am going to lean on my dad to make some very thin wooden scales for that, and then wrap them with thin leather, instead of making an all leather scabbard. I don’t want to have to sew that much cow skin if it is thick enough to stay rigid and not have that point slice right through. I might get really lazy and shape a Kydex sheath for it and leather wrap it, but I’d say she deserves a bit better than that!

Project 3: Shop knives

Another longer running, no real rush project has been finishing up some shop knives made from random bits.

The first is made from the shards of Narsil a really old scythe blade I mounted on a handle and then mistreated clearing ever thicker and woodier brush till it shattered. A large chunk is still attached to the original handle and makes a nice little chopper, but I had a good sized bit from the middle to mess about with. I liked the curved blade, sharpened on the inside, but I had to hammer flat the right angle spine and of course reshape off the broken metal ends, before re-heat treating. I had a scrap knob of apple wood to fit the small bit of spine tang, and after some grinding, it’s a pretty nice little knife!

The other is the failed practice baby from learning to forge weld. I had tried to forge weld two 1/4 bits of lawnmower blade together, and failed pretty well. I kept the badly formed knife mostly to use for a cutting edge in abusive applications, but after grinding it down I realized I hadn’t failed nearly so badly as I had thought. The edges of the billet were not welded well, but the insides were actually joined very nicely. So I decided I would clean it up a little and put on some handle scales to have a decent knife for all those things I don’t want to use a pretty knife on. I had some purple heart scales my dad had cut but made an awkward wobble in when doing so, and since I wasn’t going to use them for much anyway I slapped them on here. I then spent forever cutting, grinding and shaping them, because bloody purple heart is miserable, but I didn’t shatter a drill bit in side them, at least.

So, you know, nothing too special, but some nice little knives for doing that rough work one might have, and maybe becoming a gift for a strangely knifeless friend in need someday.

Project 4: Kitchen knives: chef’s chopper and paring.

As the day was wrapping up one of my neighbors dropped by with her doggos to say hi, and mentioned that she and her husband had a bunch of old tools in their basement they inherited from her dad, and since they weren’t the handy type I was welcome to come over and see if there was anything I could use. That being a wonderful offer to the cheapo blacksmith I thanked her and asked if I could make her anything. She said she had broken a ceramic knife recently.

Of course I neglected to clarify what sized knife, but I had some 1095 off cut from the other knives and some rather large old chisels, and so I started up new blades. One good turn deserves another!

The paring blade there is pretty much ready to heat treat, but the chopper needs more grinding with some new belts to take out those marks, along with removing a good bit of material.

I also had an idea to make some long, thin steel hot dog skewers from some old nails. However, one old nail I had, which is about 14” long, apparently had missed the acid bath to strip off the galvanization.

Yea… it’s not supposed to look like that.

There are certain advantages to working outside in the drive way, and not getting zinc poisoning from inhaling that shit is definitely one of them. Still, it was pretty cool looking!

Well, I blew past the email limit a little while ago, so I had better end it there. Spending a full 9 hours at the forge and in the shop was great, and if my hands, arms and shoulders are aching now it was totally worth it.

Go make something guys!

I feel I should should point that I wasn’t exactly happy the kids were sick, but… forge day.

He expects to have some merchandise available again as the holidays approach. If you are interested in his general work I can send his contact info over as well.

One of the reasons I have been so quiet the past two weeks is we lost both our cars, mine to being hit by an old lady and getting totaled, wife’s to a persistent tranny trouble. Hers at least was still valuable enough to trade in, but a fair sized three row of seats SUV is still a lot smaller than a minivan, especially when the kids are inside.

That would have been so much easier to make if I had a, I don’t know, maybe an anvil bick.

This hilt drama takes place a few weeks back. I was too pissed to write about it.

The hypnotic quality of finding yourself in these endeavours always comes through in your writing, Doc H. I find it oddly soothing.

I have things to make, at home 1,200km north of my current location. But there is a fuel strike and I can’t fill up. Such is life here in 🇫🇷

Beautiful Fishcalibur sword! Love Ouroboros Snek.