It's My Birthday, and I'll Make Knives if I Want To

Knives, if I want to... Knives, if I want to.

That’s right, I survived another trip round the sun. Hooray!

Part of the requisite self indulgence will be writing about making stuff.

Remember when I got poison ivy last week? Well, it wasn’t all downside, as I got some great stuff from my dad’s place:

A stump from a long dead tree, some rusty metal and wood scraps. Great success!

I am not even being sarcastic. In an object lesson in subjective value, what looks like a pile of tetanus and carpenter ant farms is in fact a wonderful pile of supplies to the right person. After some precision chain saw application, and a lot of ant killer, that stump is now a very stable anvil stand, as well as a random heavy thing to lift any Crossfit gym would envy. That reddish wood is actually purpleheart, a very hard and very pretty wood; that purplish color is natural and all the way through. That will make for some really hansom handles and grips. Precut too.

On the metal side, that little ballpeen head will be great for making another little tomahawk with my nephew, whose birthday was last month and I told him we could make an ax together as a present. That will be a lot easier than making a railroad spike ‘hawk. No eye hole to hot punch, and no requirement to forge weld in a hard steel edge. (I did a test piece our of a railroad spike, and yea… I still can’t forge weld properly.)

Most excitingly is another relic from our equine past: another farrier’s rasp. We’ll get back to that, but first, a look at the final form of the last rasp chopper after I gave it to my dad (and we stained the handle):

Even though I can see some things I want to correct, that knife/short sword (can’t even call it a gross messer, damn) came out way better than I had any right to expect. I did try to get the balance right so it doesn’t handle like a crow bar, but I lucked out and it is really nice. Just forward weighted enough to be a solid chopper, but light enough to be fast moving. (I have a nice video of my dad one shot bisecting a green tomato on a post without the tomato moving.) I am kind of jealous of the thing now.

With that in mind, I started up on my own. Although I kind of promised myself I didn’t want another multi-month project for a little, I want to make another while I still have the “I wish I had done this differently…” stuff fresh in my mind. Plus, ah what the hell, I am sure I can get it done in much less time. Why not?

THIS TIME, WILL BE DIFFERENT!

-ahem-

I want to go for one a little longer, although I am limited by the length of my forge and so the length that I can heat treat well. I think I can go a bit longer than the ~18” of the forge, as I only need to get all the metal above 1600 F before quenching, and I can get metal in it up to 2000+ F pretty well, so I might be able to just move the bits around to keep it roughly evenly heated. Plus, I have seen a trick of using a longer square steel pipe inside the forge, where you get the pipe super hot then put the blade inside the pipe to heat it. Less fuel efficient, but gets the job done. You get your blade into the super hot pipe, then dip it in the big oily pipe while its hot, and Bob’s your uncle.

(Note, the camera, propped up against a hammer on the anvil, isn’t color adjusting for the forge. Off camera I am using a thermometer to check the temp (1650+ F), but the color looks a lot darker orange than it was. Just for reference.)

Anyway, longer is better for a few reasons. Firstly, if I can get a few more inches out of the file I will have a nice gladius length, and I like Roman stuff. Secondly, and more importantly, a few more inches will make it more fun for cutting bottles etc. because I will be able to get the tip moving faster, particularly about 2” down from the tip where the center of percussion will be. Thirdly, well, it’s more elegant looking.

Here’s how that’s going so far:

Unpictured there is the thickness: still over 1/8”. That’s good, because it means I can take the blade a little longer and still keep it wide. I do want to keep the bit towards the handle around 1/8” thick, with distal taper going down to ~1/4” towards the tip. That should give me enough material to work with for another inch or two in length and a bit wider than it is above.

So, after an evening’s work at the forge (and another evening cleaning dirt and rust out of the teeth) I am pretty well pleased with how it is going.

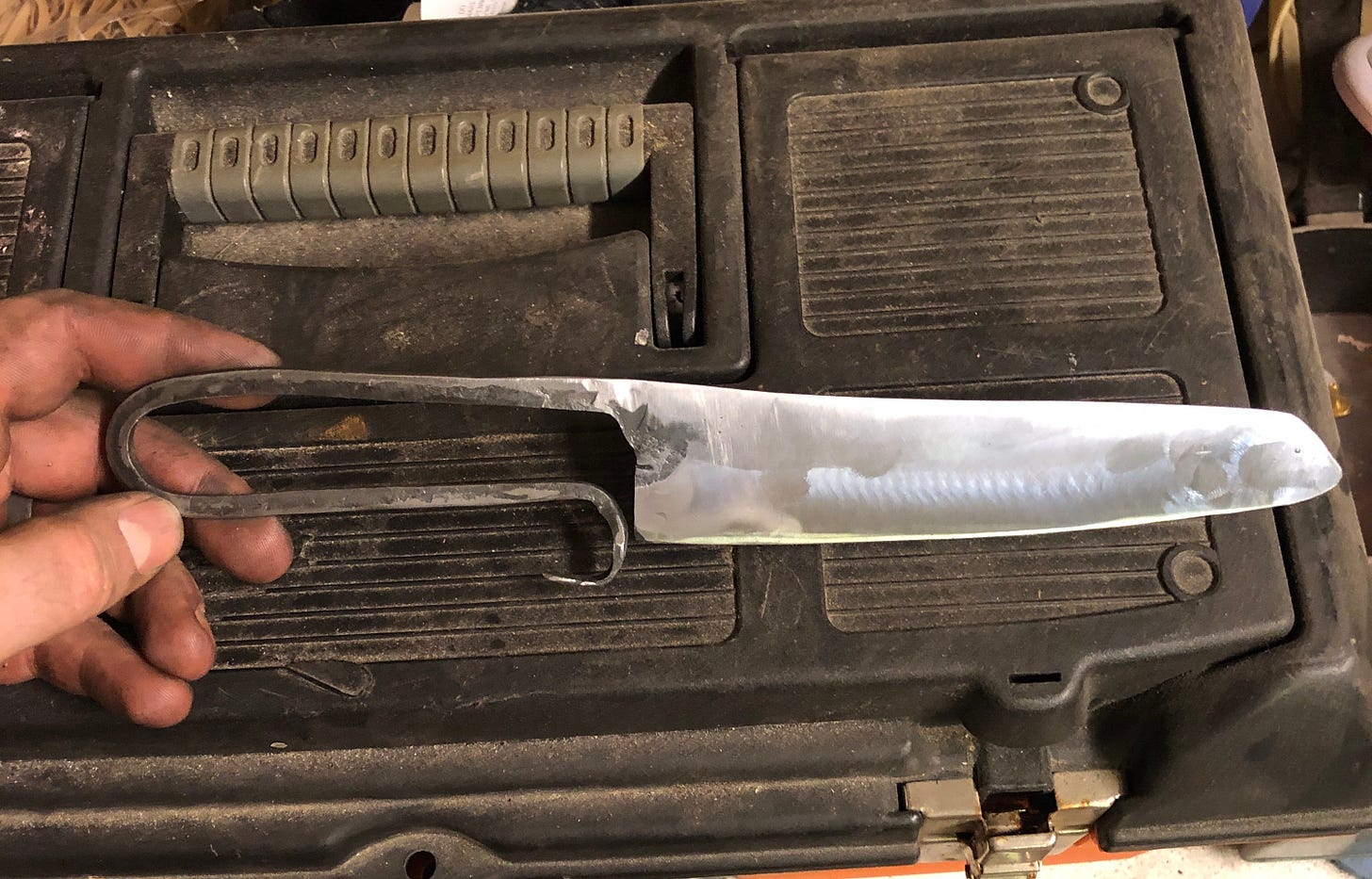

While I was at it, I finished up making another blacksmith’s knife. This time I was a lot more careful with the blade shaping, and got it a lot longer, although just a tad more curved than I wanted. Still, looks pretty, and cuts well up there in the front third by the tip.

Why am I so strangely specific about where it cuts? Well… I discovered this morning I failed to sharpen the lower 1/3. Whoops. Still, easy enough to correct. (Although I am wishing I had ground in the bevels a little more before hardening, because 1095 is a bit hard to shift after.) I am also going to redo, and probably remove part of, that little finger stop. For some reason I just couldn’t get it doing what I wanted over the anvil, and I am thinking I just don’t need much of anything to keep my fingers slipping up.

We never finish projects, we just stop working on them…

There were some other side things too: tweaking the eye of a tomahawk for my dad, working on turning a big ass bit of steel rod into a stump anvil/hardy hole beak, but not much to look at the lot of them. After a few hours of beating the steel rod looks like a “I am taking the newspaper… no wait, not long enough, give me the Bible… to the bathroom” in progress. Someday, I will own a power hammer. Or my girls will be big enough to hold stuff while I swing a sledge hammer down. Till then, I will just spend hours beating on a giant steel poo until it makes a useful tool.

Anyway, metal stuffs! Thanks for reading, and enjoy your holiday weekend!

I'll make knives if I want to

You can leave your friends behind

'Cause your friends don't like knives

And if they don't like knives

Well, they're no friends of mine

Delightful to share your joy in these endeavours. After a lifetime of avoiding ‘diy’ I discovered, 2 years ago, that I love doing rudimentary things with wood. Along with the meadow project, of which you know. Next ‘project’ is a wood store frame. Keep doing your thing 💪