I Bequeath Upon Thee Fishscaleibur!

But watery tots lyin' in ponds and distributing swords is still no basis for a system of government.

We’ve been having a spate of nice weather, and so after the girls’ swimming lessons I got out and spent the afternoon and evening working on some projects. A few needed some work:

Letter opener present for my dissertation advisor (heat treat and put on handle)

Heat treat the ugly (but kind of fun) railroad spike tomahawk head

Keep shaping the bick/stump anvil

Keep working on the rasp knife

Clearly, one of those is a lot more exciting than the others, so I did things roughly in reverse order, although since I have less time and fuel than concern for my muscles, I pretty much always work on two projects at once so one heats while I am beating on the other. I can get a lot more done, but it does result in days like today where I am pretty sure desk work is all I am up for. I need a timer system or something to keep me drinking; going over 8 hrs without taking a leak is a really bad sign that I totally missed.

But it was too much fun building towers with 2x4s and hammers while I waited, I guess :D

Anyway! Remember that rasp?

About 14-16” long (the top of the stump there is just a hair over a foot. Perfect for a meaty bowie, right?

Well, it drew out a treat, much easier than the last one:

So easily, in fact, I went a little overboard.

I think it is now solidly in short sword territory. Happily, although it is just over 26” long now (!) it retained decent thickness. By the time I got done with it the thickest part by the hilt is ~4mm tapering down to 2mm at the tip. (That is the thickness of the blade, not edge to edge.)

I was thinking to take some more in progress shots, and this one is sort of neat:

This is partway through hammering in the edge bevels, and you can see the difference between how wide the blade is at the top of the photo ad how narrow at the bottom, with almost a shoulder at that black bit in the middle. Hammering out the edge bevels added probably a 1/2 to 3/4 of an inch in width to the blade, which is why I don’t just grind them in. I hate wasting that much metal. If I keep making sword sized stuff, which I probably will, I am going to have to make a spring fuller press for putting in fullers too. That saves a good bit of material (pressing it down in the middle spreads it sideways again) instead of grinding them in which is easier but all the material just winds up on the shop floor1.

Future plans. It was time to do some serious grinding, and straightening, and tweaking, an straightening, and grinding to get the blade ready for sizing the handle bits and heat treating.

Wire wheels, flap sanders, bench grinders, belt sanders oh my!

It is still not perfectly straight, but I am beginning to despair that it will ever be so. One problem with double bladed tools like this is that both sides get wavy and you don't have a clear spine to align them against. It’s a lot of “tap this side, check if even, check if twisted the other side out, damnit, tap that side, check if even.” It’s pretty damned good now, however, and maybe some more work later in the week will get it pretty perfect.

Still… it is starting to look a lot like a sword!

Now I am left with a decision… what the hell kind of hilt and pommel do I want to put on this? It is double edged, so a symmetrical hilt makes sense, as opposed to the knuckle bow of the Bowie-ish thing I made my dad. The blade has a bit of a late Roman to early Migration Era (ahem Dark Ages) look to it, being right at the lower bound of the spatha/”Viking Sword” length (~26”, blade and handle) so I am thinking I will go with hand bits like that. That leads a problem however, that the large pommels of the era are kind of uncomfortable, which is surmountable but something to think of.

It also leads to the problem that there are a LOT of varieties.

You can see the transition from the Roman pattern round hilt and pommel to what would later be the brick shaped hilt of the viking era, becoming the cruciform hilt of the middle ages. I couldn’t find a good picture of one easily, but there are also crescent hilts and pommels as well, which look pretty cool.

Now, obviously I can’t produce anything so pretty as those swords above, but I really like the look of the ring pommel of the first sword, and the layered wood and metal hilts of the last few. At the moment I am torn between those, maybe doing a mix. I mean, hey, the thing has already blown past “Practical tool for carrying around the place to dispose of brush” and right into “Fancy thing to put on the wall and cut bottles and produce with” territory, so a bit more decoration might be in order. Fortunately I have some other work to get done, as well as procrastination instead of doing it, so I have time to noodle on it.

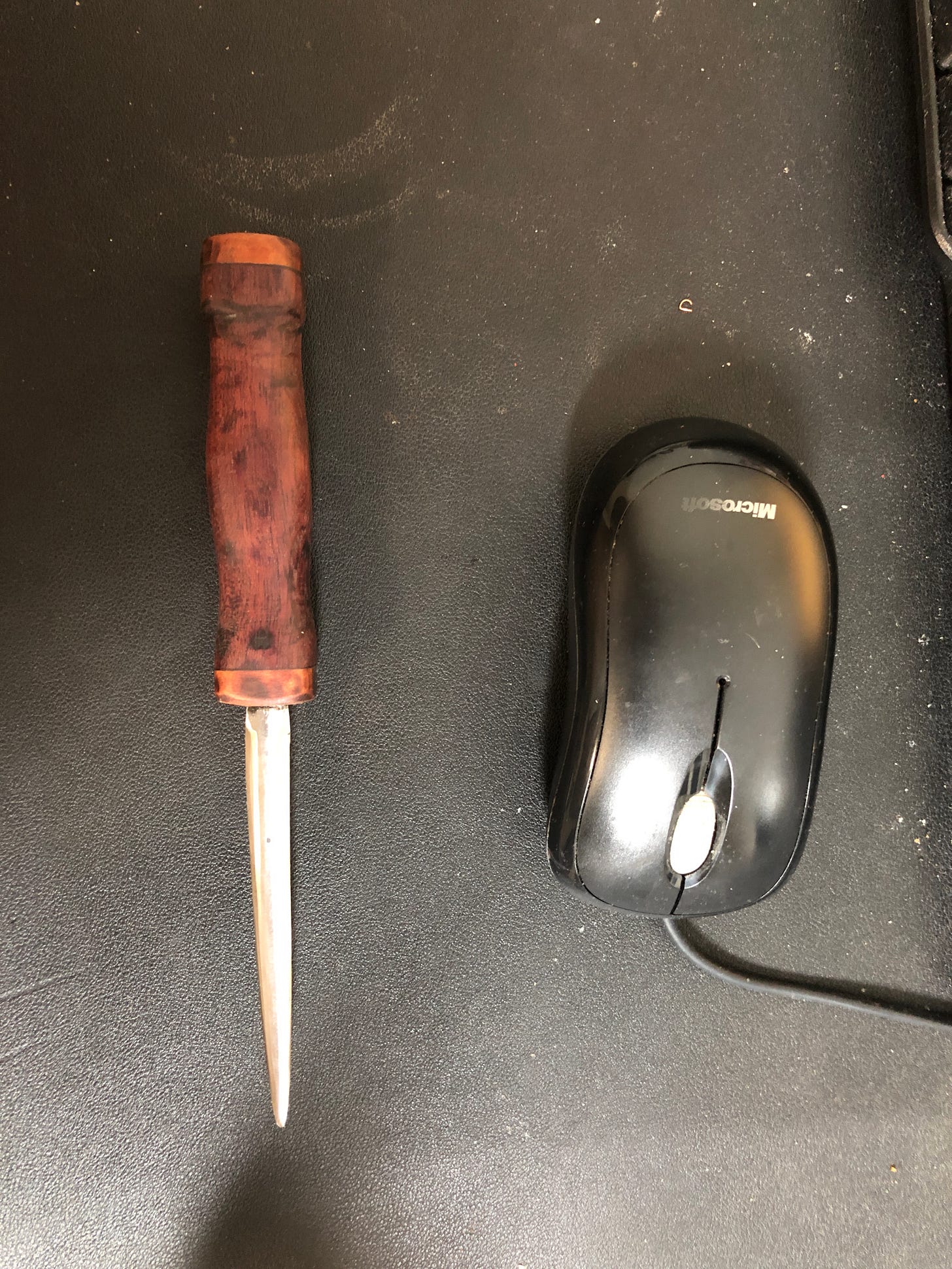

The other thing I finished was a little letter opener for my PhD advisor. I asked him what he could use if I made him something, and he said “letter opener” so… ok.

Turns out, making small things is hard! Maybe not as hard as really big things, but I might have accidentally hit a sweet spot with 6-9” knives. Those little blades drop heat like nothing, so if you aren’t super quick your piece cools off before you get more than a hit or two. Plus it is basically trying to hit a sideways nail with a hammer, only you have to hold the nail with long tongs because it is red hot. I actually was smart, however, and forge welded the little bit of 1095 steel2 to a longer mild steel rod, so I didn't have to mess with tongs. I was extra smart and riveted the two bits together to hold them in place during welding, too.

I had originally hoped to use the mild steel as part of the handle, and possibly put a bottle opener on the opposite side like a pommel to make it super useful, but the mild steel was too thin and didn’t take welding nicely. Plus I couldn’t quite figure out how to arrange the opener such that you weren’t putting a sharp steel spike into your wrist every time you used it. I mean, it wasn’t a huge problem if you were careful, but since you were explicitly to use it while consuming intoxicants, it seemed like a good way to bleed out.

Anyway, spike got made, tang got heated and jammed into some wood, spike got heat treated, and then it all got epoxied together.

About that wood…

The bits at the end are cherry, some remnants of the same stuff I used for the handle scales of my first knife. In the middle there is some purpleheart, from the piece in the picture at the top. Very pretty stuff.

Also, very hard.

Part of the trick of burning in the space for the tang in the wood is to drill a small hole that goes all the way through. You heat up the tang to red hot, push it into the hole, and it burns out the space it needs inside. A good trick, much easier than trying to drill and file the hole.

Which is good, because I broke two drill bits just making the damned hole. Yes, this stuff was hard enough to grip and snap the bloody drill bits I use to drill into steel. As you can imagine, sanding and shaping this stuff took forever. I resorted to using my bench grinder to get the shape down, along with some metal files, before just sanding to smooth the rest.

After that I put on some oil, and yay!

Bog standard mouse for scale.

Close photo examiners might notice that the blade in this picture isn’t quite so long and elegant as the last. Close readers might notice that I said I did the heat treatment above, but never mentioned tempering…

Yea. I forgot to temper the damned thing. So while I was checking out the handle and adjusting the shape I noticed the blade was leaning slightly to the side. I pressed against the tip with my thumb to see if it would wiggle or flex into position, and it snapped off in my hand. Fortunately, it wasn’t into my hand, but I still lost about a half inch. Out came the blow torch and I got it tempered, and then reshaped, but damn, what a stupid mistake. Of course the thing is very thick compared to its length or width, so it doesn’t bend and flex like a sword or long knife might, but still, I am lucky I didn’t pay a higher price for that stupidity.

Even slightly stubbier, however, it will still open a letter like a boss. Possibly also the letter holder, although I didn’t sharpen it too much. I have a slight rectangular mark in my index finger where the snapped blade pressed in that still hasn’t gone away, so… maybe not all tools need to slice unsupported paper.

As for the rest of me, I need some more to drink, and some more coffee. Thanks for reading!

And in my hair, on the back of my neck, up in my nose… it’s amazing where that shit gets to. If I had to get an MRI I would probably leave a coating on the inside of the machine at this point, no matter how many showers I have ahead of time.

Because every letter opener should be able to hold an edge that you could dissect small animals with, just in case.

I didn't know you were called Dennis!

There is an old master knife-maker in Sebastopol CA who used to teach weekend workshops at his house, Karl Shroen. He wrote a book on using exotic high tech steels in a “backyard” low tech situation. It is out of print but I see it on line. You might find it interesting.